09 Oct 2018

Written by Lisa Bläcker. Posted in Krah - News

Krah America Latina SA has faced the challenge of developing PE100 pressure pipes up to 10kg/cm2. Considering that the resulting stresses are proportional to the pressure load, we started by carrying out a finite element study on a DN800 NP8 pipe

Method: The socket - spigot joint corresponds to a pipe with nominal diameter DN= 800 mm and 43 mm thickness, subjected to an internal pressure of 8 Kg/cm2. The material of the union of the socket - spigot and the pipe is Polyethylene PE 100, Modulus of elasticity E = 2500 Kg/cm2 (long term), Poisson coefficient: 0.45.

The study was carried out for the union by electrofusion, in three different positions of heating element, being the gap between the heating element and the bottom of the socket: case 1 40mm, case 2 60mm and case 3 20mm.

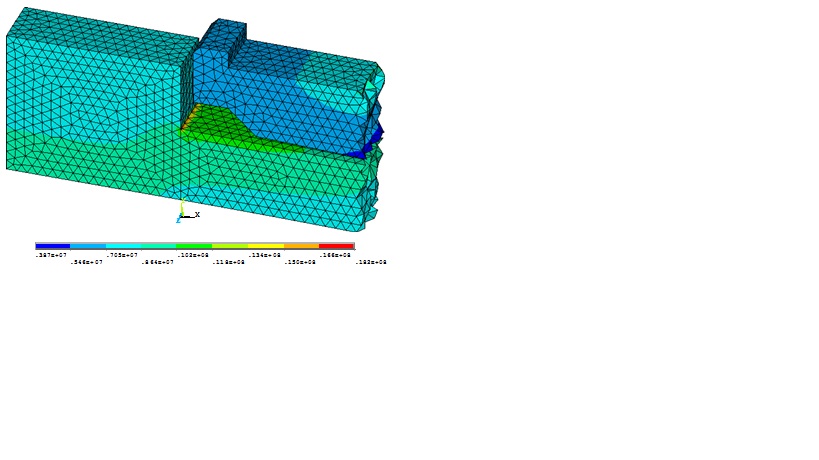

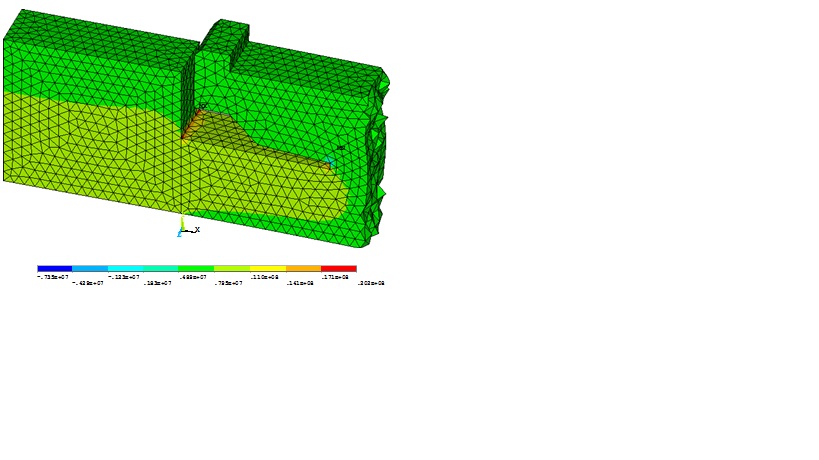

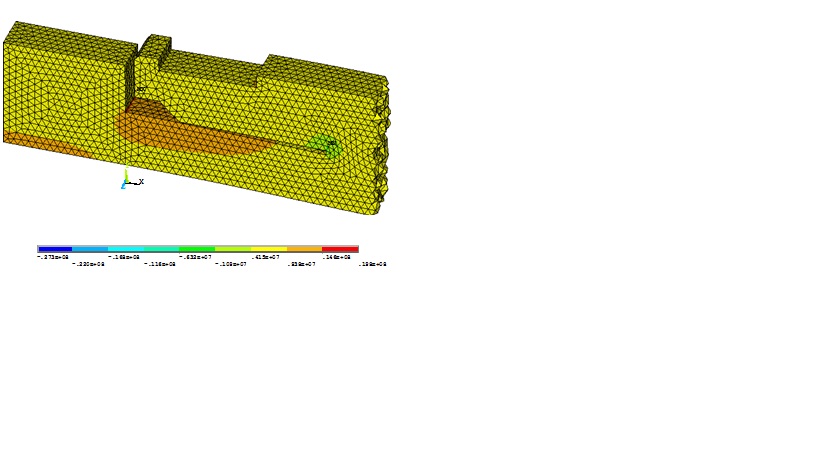

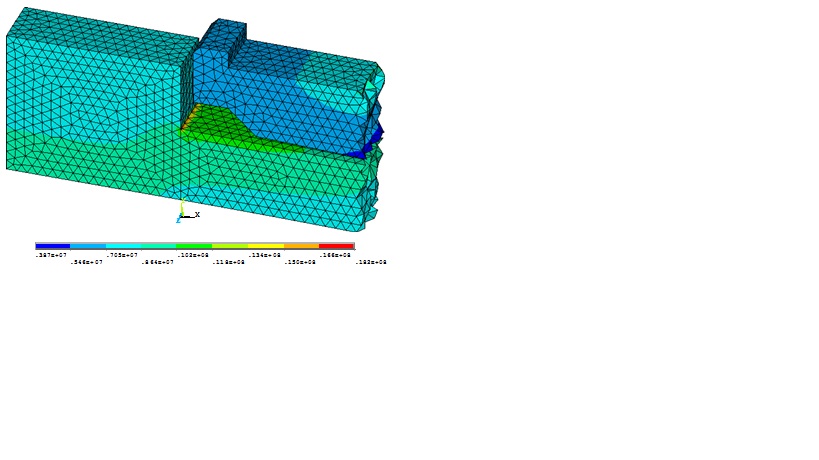

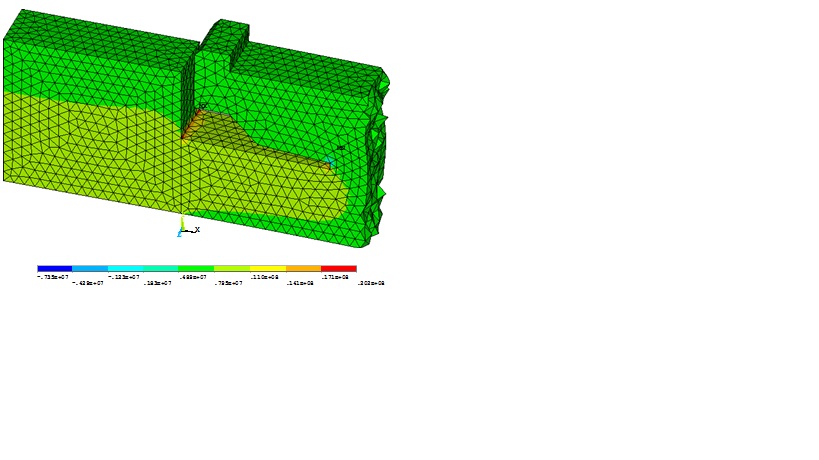

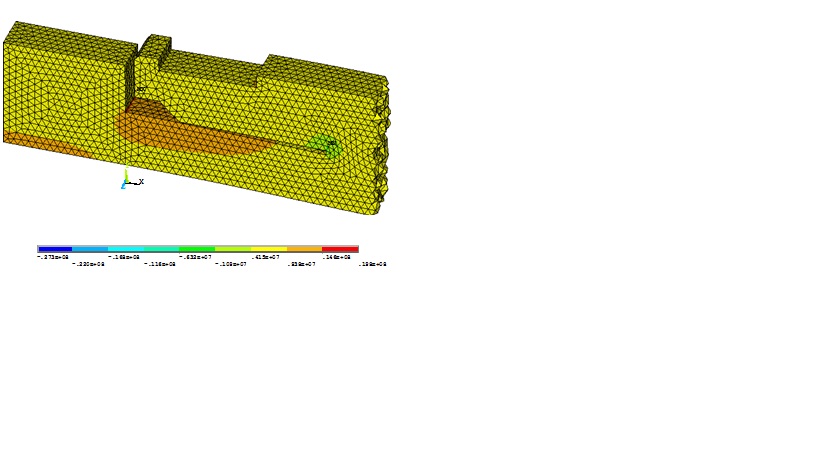

In order to carry out the study of stresses and deformations using finite elements, and given the revolution symmetry of the pipe, a model of π/2 of the pipe was made. A type of solid tetrahedral structural element was used. This element has quadratic displacement behavior and is suitable for models with irregular meshing. Each element is defined by ten nodes having three degrees of freedom for each node: translations in the nodal directions x, y, and z. The element also has capacities for large deformations, plasticity and creep phenomena.

The mesh has been made with an element size of 3 mm, resulting in a number of 58,820 elements and 89,327 nodes.

Results: The stresses in annular, radial and longitudinal directions were determined for the three cases, resulting in all the cases the annular direction the most important one. Consequently, their values are reported below.

CASE 1 CASE 2 CASE 3

Continue Reading