Krah Pipes

The high-performance plastic pipe production technology by Krah Made in Germany

Leak free, sustainable, homogenous and flexible Krah Pipe System

Since generations the mankind is busy by transporting water/sewer or any other liquids from one point to another point. The challenge was always to assure a conveyance system without fails and leakage. Most pipe failures were occurring on the joints through corrosion or cracks on the rigid inflexible pipe material.

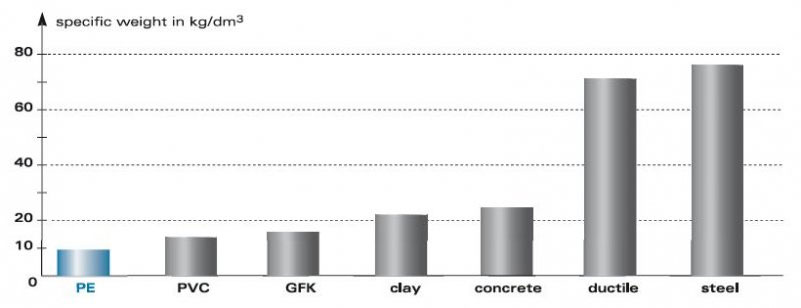

Over the last decades, the inherent weaknesses of concrete, clay, ductile, PVC and steel caused tremendous problems in existing water supply, sewer pipes systems, as they tend to be brittle or are too sensitive for aggressive chemicals and soil conditions. Leakages have become a common occurrence worldwide in water, sewer and other large diameter pipe applications. In addition, they have an unprofitable relationship between cost and benefit due to short life time and high maintenance costs.

Krah Pipes are made out different grades of pure Polyethylene or Polypropylene who are providing superior properties against corrosion, leakage, pipe displacement and ex-infiltration. In addition to the permanent solution that lasts through generations, the Krah piping system is able to provide a sustainable, environment friendly and economical solution with its wide-ranging fields of applications, f.e. water supply, sewer systems, drainage, storm water management, sea outfalls/intake, manholes and reservoirs.

In order to meet the demand of the at least 100 years leak free, sustainable and flexible pipe system, Krah Pipes are produced with an integrated electro fusion joint system, which assures a melting of the pipes to a homogenous and monolithic pipe system.

Krah Pipes can be produced from the following thermoplastic materials:

High density polyethylene (PE80 and PE100))

Polypropylene – random (PP-R, PP-B)

Polypropylene – homo (PP-H)

Flame retardant polypropylene (PP-S)

Other materials can be used after prior acceptance of the producer and a third party for quality control.

Advantages

Advantages of Krah Pipes

Krah Pipes are made from HD-PE100 (acc. to DIN16961, EN13476, ASTM F894, ISO9969 and other intl. standards) are produced with an integrated electro fusion joint socket and spigot. The pipe is completely helically extruded with profiles or solid wall, tailor made for any kind of application within the standards. The pipes have no welding seams or any weak points and are completely monolithic made from high density PE100. There is no recycled mixed material used, to assure an excellent quality of the pipes which is assuring the service cycle of minimum 100 years.

Jointing Technologies

Most Krah pipes are produced with an integrated socket and spigot.

These are adaptable to the following listed jointing technologies. As various tests and decades of experience have shown, the jointed part of a pipe system is usually the most vulnerable part. Here, the pipe is mostly exposed to possible leakages. The Krah system offers a well-known connection method developed further for large scale application which eliminates these concerns by guaranteeing a solid homogenous pipe line.

Applications

Manholes are used for maintenance and inspection of piping systems. Basically they can be clustered into two main categories.

System shafts are used for smaller dimensions whereas tangential shafts are used for rather larger dimensions. They basically differ in their position/location towards the pipe.

All Manholes are designed in a cylindrical shape. They are designed to take full highway traffic load (HLC60) where the reinforced concrete top plate rests directly onto the vertical wall of the construction. PEHD Manholes and chambers can also be installed in areas of high ground water levels.

Co-extrusion

If requested all pipes can be manufactured either with a bright, inspection friendly or an electro-conductive inner surface made by the co-extrusion process.

The co-extrusion provides an inspection- friendly, bright inner surface and at the

same time a long term UV-resistant outer surface (for example for the storage

of pipes outside for a long time).

Diameter

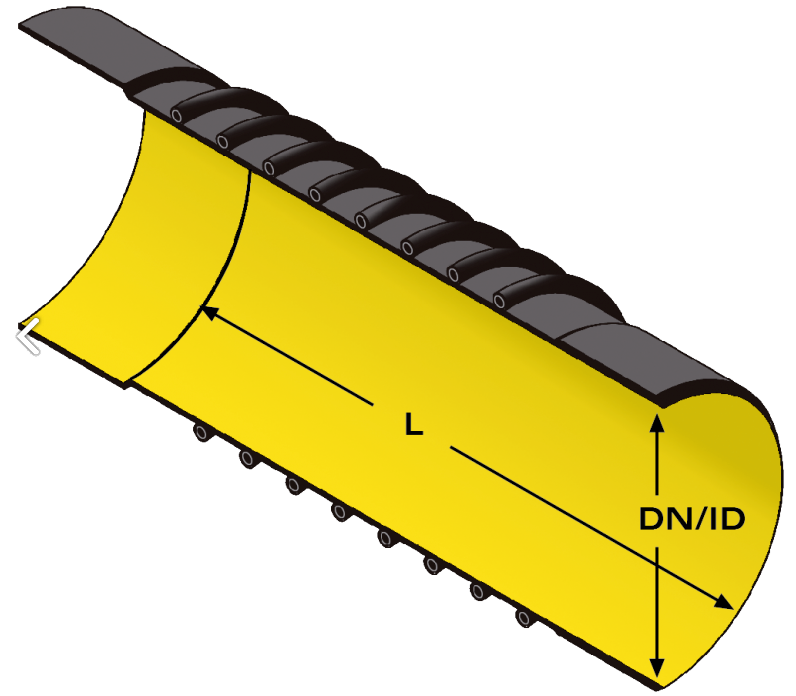

Krah pipes can be produced steplessly at intervals of 100mm with

internal diameters (ID) ranging from DN/ID 300mm to DN/ID 5000mm.

Krah pipes can be produced steplessly at intervals of 100mm with

internal diameters (ID) ranging from DN/ID 300mm to DN/ID 5000mm. The nominal

diameters (DN) coincident with the internal diameter (ID) of the

pipe, because in case of any change in the design of the pipe the

wall thickness can be increased or reduced while the internal diameter

remains the same.

Flexibility/Deformation

Elastic pipes can react to changes in their environment.

Due to the deformation performance, the load is distributed

to its surroundings and the force acting on the pipe will be diminished.

Within a short time there is a balance in the area around the pipeline and

the deformation comes to a standstill. Plastic pipes react very flexibly to static

loads, while the loads do not concentrate themselves on the pipe, but are diverted

to the surrounding soil. Flexible pipes still work when other rigid pipe

systems already show damages like breaks or cracks.

Hydraulics

Due to the smooth anti-adhesive inner pipe surface the inner diameter and hydraulic properties of Krah pipes will remain constant regardless of the wall thickness or the profiles.

The nominal diameter (e.g. DN/ID 500) corresponds to the respective inner diameter according to DIN 16961. Compared to other pipe materials like concrete smaller

diameters can be used, which means that costs for material and installation can be reduced significantly.

Internal pressure

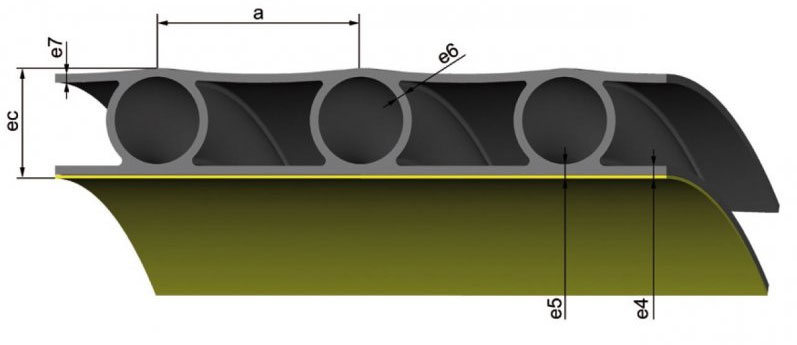

The Krah pipe system can withstand low working pressure up to 3 bar, depending on the thickness of the waterway wall (e4,e5).

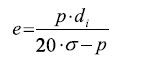

Equivalent to DIN8074 the hoop stress formula can be used with

minimum (e4,e5) as the minimum wall thickness of the A1 pipe, or

the minimum wall thickness of the waterway for A2 pipes.

e = minimum wall thickness

p = internal pressure

di = internal diameter

σ = permitted strength (MRS/C)

MRS = Minimum Required Strength

C= Safety Factor (for water 1,25)

Length

The standard laying length (L) of the Krah pipes is six meters, because in this way they are easy to handle, store and transport.

In addition it is possible to continuously produce any length between one and six meters. The longer a pipe is the fewer joints are necessary and this is advantageous for the pipe installation. Moreover it is possible to deliver the pipes already jointed, whereat the installation time on site can be reduced significantly.

Lifetime

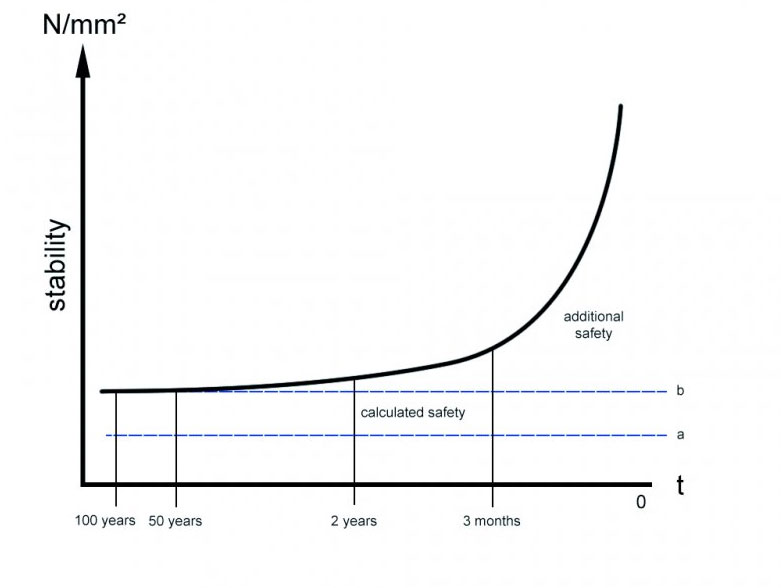

The lifetime of the complete Krah pipe system for gravity and low

pressure application is 100 years.

Basically every component is designed for a 50 year full and constant load case.

In the upper shown diagram you can see that the stability of the pipes are designed for a usage of 100 years (a), including a calculated safety margin. A stability (b) is reached - with constant load, in our case due to the usage of polyolefins we have an additional safety. As soon as the load is released the time is starting again, and

you have the extra safety again.

Material

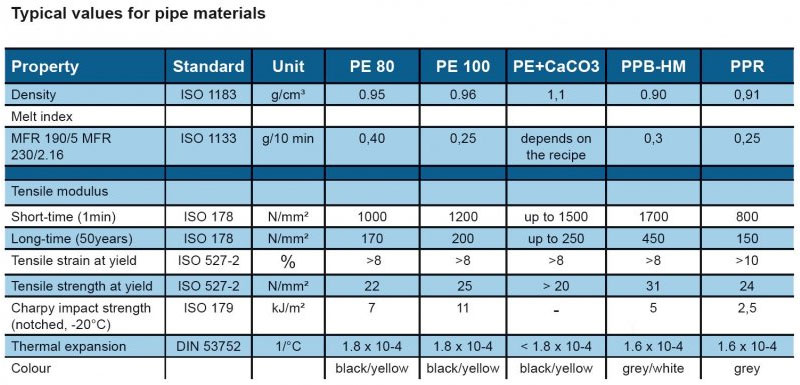

Polyethylene (PE80 and PE100) and polypropylene are thermoplastics with excellent properties for the application with water and sewer, as well as for the fabrication of containers for liquids and solid materials.

The environmentally friendly plastics polyethylene and polypropylene

are resistant against many chemicals and are very suitable for conveying

and storing various liquids.

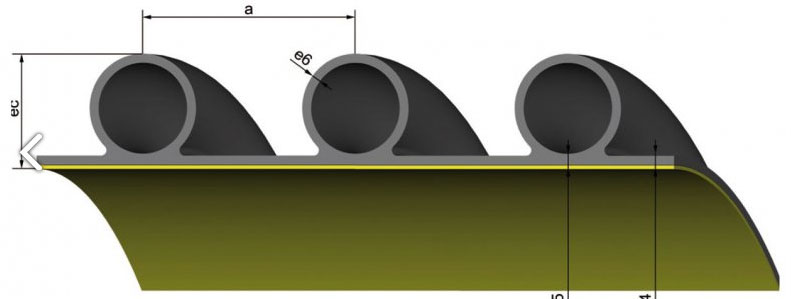

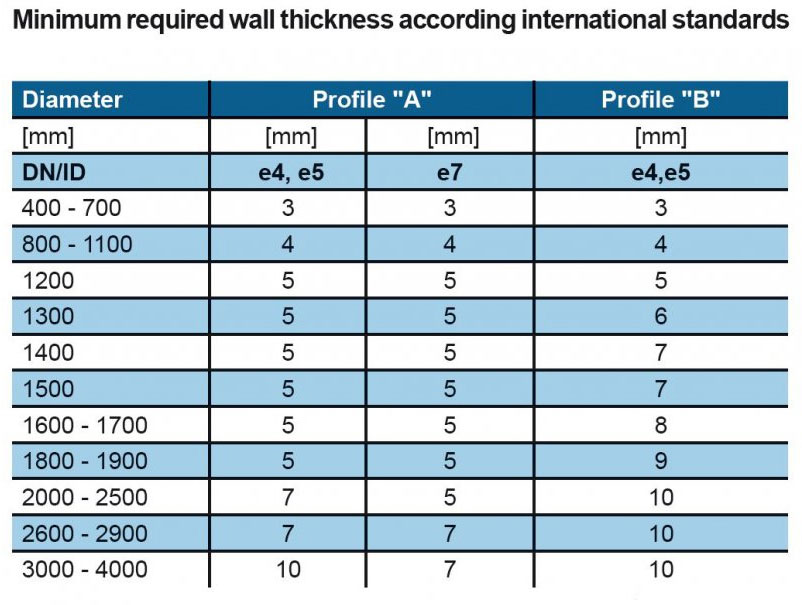

Wall thicknesses

Both profiled and solid wall pipes with wall thicknesses of up to 300mm can be produced.

The quality of the pipe is highly dependent on the quality of the waterway wall, therefore all Krah pipes are usually produced with a minimum waterway wall of 4mm.

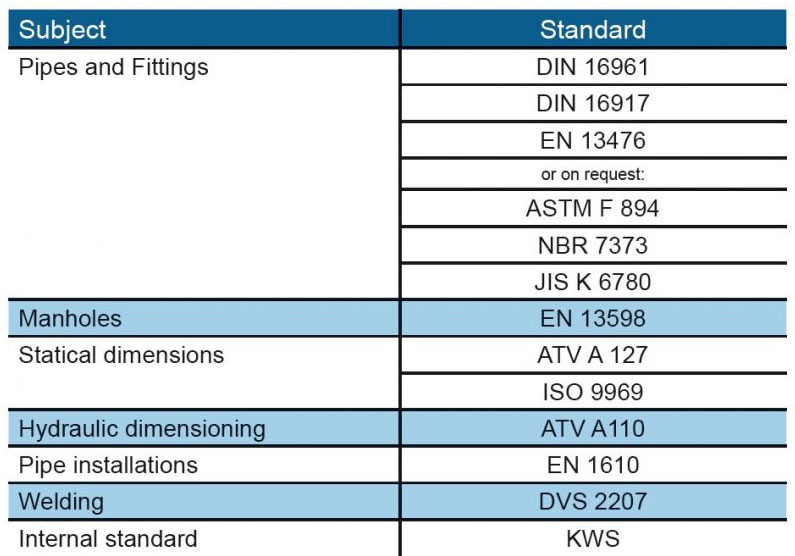

Standards

The Krah pipe system is designed to meet the requirements of present applicable international norms and standards.

The Krah Pipes GmbH & Co. KG is member of the major standardization committees to guarantee that the pipes are corresponding to the standards, but also that the standards are corresponding to the pipes.

The Krah pipe corresponds to the following international standards:

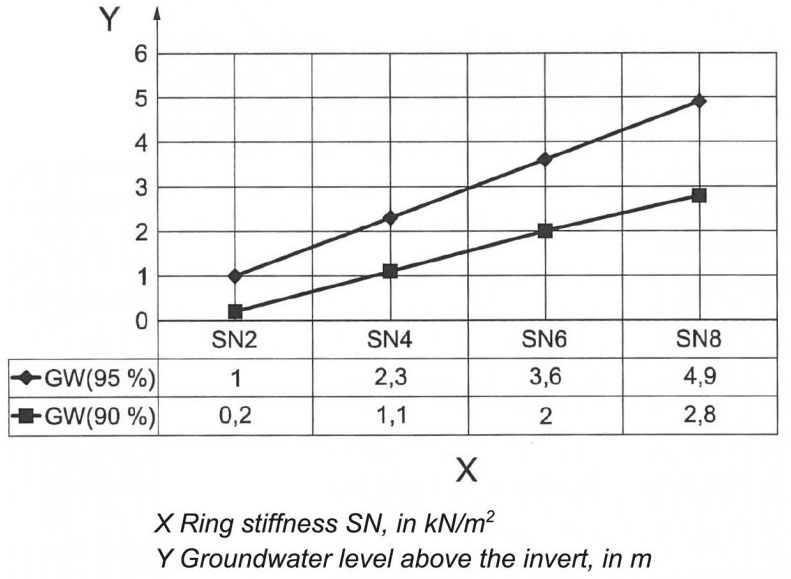

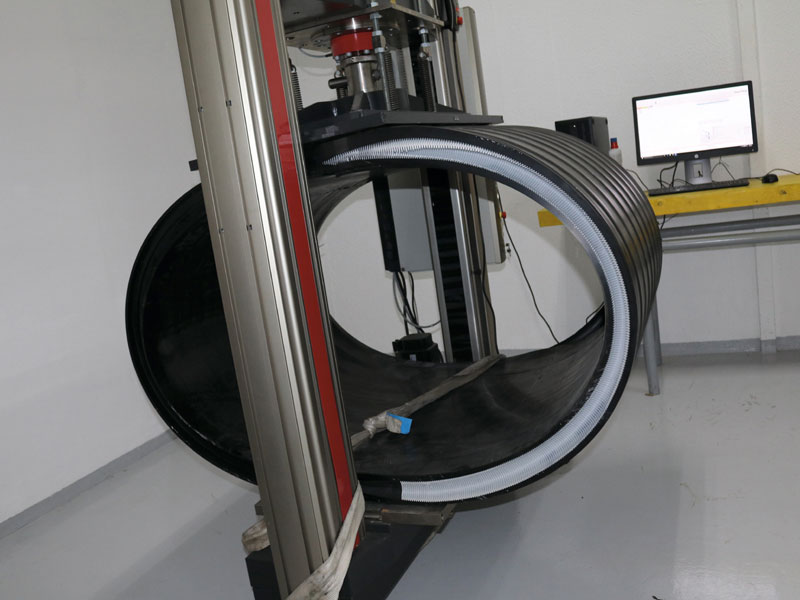

Stiffness

According to different norms and standards, the pipes shall be designed according to nominal ring stiffness classes.

(SN) like SN2 (only for pipes DN > 500), SN4, SN8 or SN16 (according to ISO 9969), or other standard stiffness classes (DIN16961, ASTM F894, NBR 7373 etc) not depending on the testing method (constant speed or constant load).

Do you have any questions?

Do you have any questions or would you like to be advised on one of our products?