Specific design of chamber system directly installed to a working sewage network

The city of Sundsvall in Sweden is continuosly investing into renovation and development of its sewage and stormwater networks. The project Strandgatan, as one of those development projects, was comprised of ID1000, 1200 and 1400 pipelines installed with the Krah integrated electro fusion connection. In addition to the pipelines several chambers were to be installed alongside with the pipes.

During the final design and before the installation phase, we learned that the local municipality is facing a challenge related to the installation of the pipelines in this specific project. Part of the pipelines in this project were installed as a new independent network, other part was designed to substitute a actual working sewage system. This provided a big challenge, as a sewage network in use cannot just be cut off. A complete solution was required to install the new pipeline and switch from an old network to the new one while keeping the stoppage time as short as possible. There was an additional challenge to solve the question at hand – the location of the pipelines to be merged would have new pipelines criss-crossing the whole area available for us, so we needed to consider also the vertical alignment of the pipes in the area.

A special solution was developed by KRAH Estonia and presented to the Sundsvall municipality by Wavin Svenska AB, our partner in Sweden. The solution comprised of two prefabricated chambers joined to one chamber system:

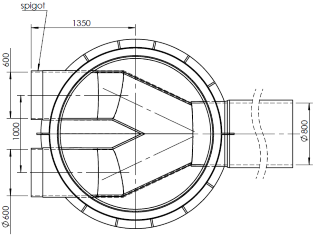

- ID2000 chamber with ID800 inlet and 2x ID600 outlet pipes. The ID800 inlet pipe was a special design solid wall pipe to be connected to an existing concrete sewage pipeline DN800. ID600 outlets were to be jointed to the network by Krah electrofusion connection. The chamber bottom was to be executed with the half pipe flow path design, corresponding to the inlet and outlet diameters.

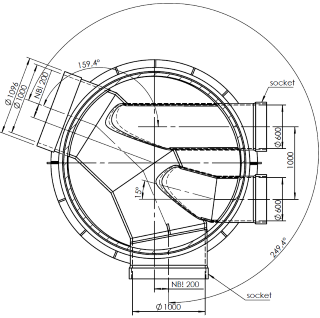

- ID2400 chamber with 2x ID600 and ID1000 inlet pipes and ID1000 outlet pipe. The chamber bottom was to be executed with the half pipe flow path design, corresponding to the inlet and outlet diameters. All inlets and outlets were to be jointed to the network with Krah electrofusion connection.

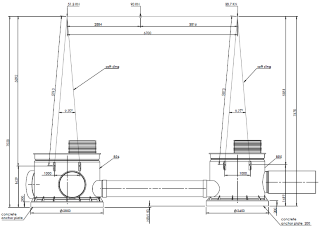

The two chambers where joined and shipped as one complete system, ready for the installation including for example concrete base slabs. Basically it was finished to a plug and play level – just to be connected to the existing network in place. The chamber system was delivered with exact strapping and lifting instructions.

At the installation site an existing sewage pipeline was cut off and blocked. The flowing sewage water was temporarily pumped to an old receiving chamber. The chamber system produced by Krah Pipes was lifted from the truck directly to the final installation area and connected to the old sewage network from one side and to new network systems on the other side. The local municipality had to cut off and redirect the sewage flow for the duration of those installation works, totalling mere 5 hours. The sewage flow was restored from the old network to the new one immediately after the installation was finished.

Author:

Peeter Kirtsi

Krah Pipes OÜ