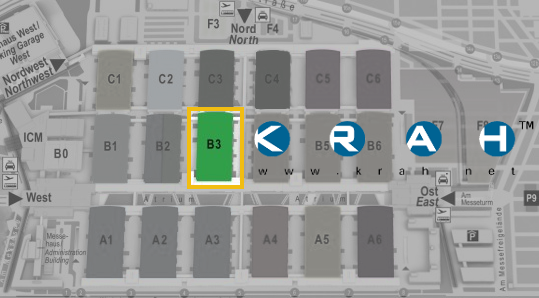

Corsys Plus Pipes in reconstruction

Rublevskaya water treatment station has been operating since pre-revolution times and still remains the main source of potable water for Moscow, Russia’s largest metropolis. Today there are plenty of new materials and technologies available for water supply and water disposal which can extend pipeline operating life by up to 50 years or more. Implementation is going slowly, which is why the number of worn networks is still significant. The Rublevskaya water treatment station is no exception. Having reached a certain stage of operation, it needed restoration of its filtrate ducts – underground water mains of rectangular and circular cross-sections made of reinforced concrete. Specialists at Mosvodokanal confirmed the option to use circular cross-section plastic pipes in these conduits and ID 1400 mm and 2000 mm were approved for the various sections. They had to choose pipes and fittings for operating pressures up to 0.15 MPa, and find solutions for the following non-standard tasks:

• Installation of pipes, fittings and branching from inside, because opening of water conduits was only planned at places with bends and in chambers;

• Connection of the new pipeline to the old one;

• Pressure testing of the new pipeline conducted as for a pressure pipeline.

CORSYS PLUS pipes (pressure version) met all the requirements. These pipes fully comply with GOST R 54475 (used for the production of non-pressure pipes). In addition, they also go through an in-house pressure test similar to GOST 18599-2001 for at least 100 hours at a temperature of 20°C. This allows the use of CORSYS PLUS pipes for pressure systems with operating pressures up to 0.6 MPa. The reliability of the CORSYS PLUS pipes connections is ensured by electrofusion using special electric heaters integrated into the sockets of the pipes. This is the only type of connection that meets the requirements for a new pipeline.

|

| Underground water conduit to be reconstructed |

|

| Welding of CORSYS PLUS DN/ID 2000 mm from inside using two welding units |

Krah Pipes re-used as Flower Containment System

Krah Pipes re-used as Flower Containment System