First Flush Rain Water Systems

Centraltubi S.p.A. (Italy) has shared with all Krah Community Members its experiences about the accumulation and treatment systems developed and installed for the 1st flush of rain waters.

Considering the European regulations for environmental protection (in these days under review), the definition of “1st flush of rain water” was passed as follow: “the amount of rainwater precipitated in the first 15 minutes of the meteor event”. Thus, two different systems widespread in Italy were shown: system 1 operating by water accumulation, and system 2 operating continuously.

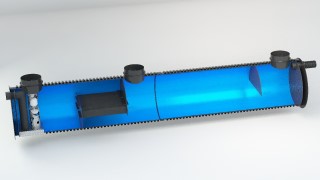

System “1” consists in an accumulation volume, sized for storage the quantity of water calculated on project (minimum: 15 min. of rainfall x 5 mm thickness x drainage surface considered). The rain falling on waterproof surfaces (roads, parking, airport runways, harbours, logistic platforms etc.), washes the surfaces and thus transports very aggressive polluting materials. After the rainfall these surfaces are considered “clean”; they will be considered “dirty“ again after 48 h. So, the water collected must stay into the accumulation volume for at last 48 h. During this period, the water is sent by a pump to an external system dedicated to oil and sand separation or, when available, in a waste water treatment plant. Water depuration level is depending on the efficiency of oil and sand separators elements. The accumulation volumes (tanks) are realized with HDPE Spiral pipes made with KRAH technology, where modularity allows to size any volume desired, thanks to the electrofusion socket system that allows a 100% water tightness.

Completion and management of the system

Some components are necessary to complete and manage the system: manholes for inspection and cleaning + the first manhole behind the tank must be equipped with a by-pass system; closing valve and pump with electrical cabinet. There are some waterproof surfaces that must be considered always “dirty” (polluted) also after 15 min. of rainfall, like car demolition areas, gas stations etc. so, in this case, it’s necessary to treat all waters drained.

PE plate stops the water turbulence

System 2 provides to treat a flow rate (litres/second instead a volume) into a tank, where water passes through and the separation of pollution materials happen through floating (light liquids, leaves, papers, woods …) and for sinking (sands, stones, metals ….). The tank is inside equipped with a PE plate to stop the water turbulence immediately after the inlet. In this surface will be accumulated all floating wastes: papers, leaves, plastics etc. that can be extracted from the manhole above. The water flow slows down into the big volume of the tank, so light liquids will float on the surface and the heavy materials settle at the bottom. To have the best separation efficiency it’s necessary to minimize the turbulence of the water, so it’s preferred to use the biggest diameter possible, to reduce the speed of the water flowing; small diameter pipes need to make longer tanks. Lamellar packs and/or coalescence filters can be installed into the tank, to have a better filtration of smallest parts which failed to float in surface, or settle to the bottom of the tank. To go out of the tank, water must flow into an apparatus equipped with a special floating valve, set to float in the water, but not in light liquids. In case of too much accumulation of light liquids, this layer grows from the surface towards the bottom, so the water floating valve gradually descends, until it closes the tank outlet at the established level, so as not to let the oils escape too.

If water continues to flow inside, its level grows into the tank and will go out from the by-pass of the manhole installed before the water entrance in the tank. An automatic gravity system to extract continuously the light liquids from the tank has been shown.

Oil and sand separation systems installations are significantly advantageous for installator when made with spiral pipes. Their main advantages are:

- Handling and installation (facilitated by the lightness)

- Faster installation time

- More working site safety

- Ready to install (tanks arrive already complete of everything inside)

- Modular system (= no volume limits) easy and fast to connect

- Affordable watertight connections thanks to the electrofusion socket system

- Technical and design support

- Less workers operations in the working site

- Safety

- HDPE durability and tolerance of the pipe settlements

- Gravity system (> sustainability)

- Little working time thanks to the easy system and supporting given from producer

- Possibility to use recycled materials (standard EN 858 don’t regulate it), so “green” certifications can be provided

Maintenance plan of the network operatior required

All systems separate water from pollution materials, so these materials will be accumulated. A maintenance plan from the network operator is therefore necessary to check and clean the system. Frequency of controls are depending mainly on the number of rainfall and the cleaning status of surfaces. At the beginning, we suggest everyone carries out the first checks every 6 months (more frequently is better), in order to form an idea of the seasonal situation to draw up a correct final maintenance plan.

Marco Maroncelli

R&D Team of System Group