Many bridges over troubled water to be crossed in the last 50 years !

Once upon a time, in the early 1960’s, a German engineer in his early twenties became very courageous and went from a small village called “Niederdreisbach” in the mining region of the Westerwald to, formally known as Persia, today Iran, to work for a Swedish company.

While Karl Heinz Krah was getting settled in Iran and was busy with his challenges in a foreign country, far away from home, his wife and his first son also moved to Iran to live there together. After several years of commitment in the Middle Eastern country, family Krah decided to come back to their home village in Westerwald, bringing a lot of engineering experiences and cultural influences with them.

Upon his return in 1968, Karl-Heinz founded his own engineering company with a small workshop, situated in a former old mill in Niederdreisbach – in the house where he was born, as one of five children. With simple engineering and development services for the local metal and machinery industry he started.

With an increasing demand and more production space was needed. Thus, he bought some land directly on a river – called “Daade”, in the neighbour village: “Schutzbach”, a small town of approximately 500 inhabitants. The first production hall was built in 1970 as a first step to an international operating company.

It was in the early 1970`s, when the company Bihler from Bavaria, Germany, the world's leading system supplier for stamping and forming, welding and assembly technology, was looking for a reliable partner and producer of special tools for their systems. They found the right supplier in Karl-Heinz Krah and they entered a long-term cooperation, lasting into the 21 century. With this cooperation, the business was growing and the company was able to invest in, at that time, sophisticating and most modern machines. With this being the only company in this region that could offer those kinds of works and services, it was obviously quite well-known and successful.

In the 1980`s the company “Karl Heinz Krah” focused on the development and manufacturing of machines and big tools. During this decade, they have started to deliver tools for the plastic pipe production in Germany. Bauku, a former German pipe manufacturer approached them as they were looking for a reliable supplier for tools and machines for the plastic pipe production.

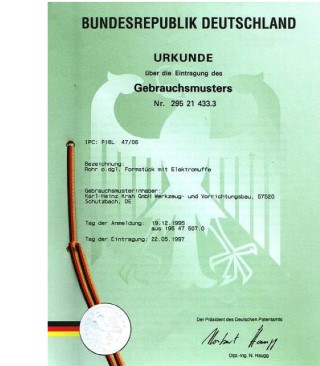

The company dedicated itself more to this industry, earning itself a good reputation by high-quality works and innovations in this sector. During those years, the plastic pipes where still a niche product, but Karl-Heinz Krah fell in love with it and concentrated on the spiral wound production system for plastic pipes, which strongly helped this product to gain worldwide recognition and success over the coming years. The first CAD-system was already installed in the 80’. With the growth of his business, he started developing new solutions in machinery and tools for the plastic piping industry. This was the birth of the company Karl-Heinz Krah GmbH, Werkzeug- und Vorrichtungsbau in 1991. In the last decade of the 20 century, after several years of experience and developments, the next milestone of the company was set by deciding to keep the focus and concentration on the field of pipe production technology.

During those times the business relations between Krah and Bauku came to an end, but even in difficult days, Krah strictly kept the idea of developing a unique pipe production technology.Thus, Krah has developed the double die head technology for the production of the profiled large diameter pipes and increased the variety of pipe designs to cover more market segments and application areas. Furthermore the production process was optimized and the first spirally wound pipe production technology with a defined workflow was born – both single pipes as well as series of pipes could be manufactured on one and the same machine.

The pipe production technology based on this innovative solution was already able to produce large diameter profiled pipes with only one machine for the diameters of DN 300 up to 3000 mm in polyethylene and polypropylene material. First, Krah was laughed at and the market didn´t take the new development too serious, but with those developments it became more attractive to pipe end users and finally was a great success for Krah and the first machines with this brand-new innovation were soon sold and installed for example in Iran and China, followed by many other orders worldwide. Krah pipes became quickly famous worldwide and the key player in the world´s pipe market.

Beside the machine manufacturing, Krah company entered the partnership with the Frank Company, which is a well-established pipe producer in Germany with a great market infrastructure, to have a second mainstay and stay close to the end product. This partnership, the pipe production company Frank & Krah Wickelrohr GmbH, started to produce profiled pipes in the Krah headoffice in Schutzbach and delivered the pipes to all different kinds of pipe projects throughout central Europe.

Together with the company Frank the integrated Electro Fusion socket and spigot were developed and implemented in countless projects. The integrated Electro Fusion socket and spigot became very popular and a lot of international pipe manufacturers were interested to produce Krah profiled pipes.

Furthermore the unique co-extrusion inside layer was invented to guarantee an inspection friendly inner pipe layer, which since those days has been an indispensable condition for modern pipe systems.

The continuous growth and development of the company caused the extension of the product range, which also required more space at the head office in Germany so that another new hall was built.

In the Millennium year 2000 a new generation of Krah entered the company. The youngest son, Alexander Krah, who had always been engaged in the company before, finally became, together with his father, the general manager of the Krah company. Alexander Krah has graduated at Siegen University in Business Administration and developed the marketing and product strategy of Krah group to a complete turn key product.

Due to the constant growth of the industry and the lack of space, Frank&Krah decided to move out of Krah premises in the early 2000 and moved to Wölfersheim. Krah remained to be a shareholder for some more years. In 2008 Krah developed the technology to produce pipes from DN 300 mm up to DN 4000 mm. That year, the annual turnover reached more than 20 Mio EUR. Over the years, the performance of the machine was steadily improved, starting with approximately 200 kg/hr, having, for now, reached 1500kg/hr for a pipe DN/ID1000 always optimizing the pipe weights.

Furthermore, the Krah profiled pipe manufacturers established the Krah Community together with the Krah Group, to strengthen and develop their knowledge in large diameter pipe production and application. A tight network of pipe producers was built, and annual meetings are being held, each time in another Krah pipe manufacturing location worldwide.

In 2015/2016 the company group was re-organized and re-structured in small units. This was a result of the unfortunate insolvency of Krah GmbH, caused by single effect of a judgement of an arbitration court. So the Krah company is not a “one-man ship” any more, but a fleet of small but strong and quick boats now. Employees were offered the chance to purchase shares in one of the companies, which was willingly accepted and even created a feeling of shared commitment and belonging. During those difficult days we were very happy to have our house bank, the Sparkasse Westerwald Sieg, who supported us and trusted in us and our products.

Beside the machine making part a new division was founded: “Krah Pipes” as a connecting link between the machine manufacturing and the pipe producers. A lot of new developments Human skilled staff is the success for the group in the future.and patents in the pipe field are made there. Krah Pipes is a registered trademark and is now already used by several Krah pipe producers worldwide.

In the past 50 years, Krah Germany has successfully installed and commissioned around 50 pipe production plants worldwide, on all continents (except Antarctica yet), having created long-term customer relationsips and partnership with well known and local market leading pipe producers like Dainippon Plastics in Japan, Polypipe in the UK, Polyplastic in Russia, Frank in Germany, Firat in Turkey, System Group in Italy, just to name a few.

The company itself has a total area of 33.300 m², whereby the production halls make up 7500 m²,

Today, the Krah Group Germany has a total staff of around 60 people, employing all different kinds of skilled people, from toolmakers, metal workers, mecatronic engineers, electricians, .engineers, technical drawers, salesmen, secretaries, accountants, purchasers, just to name a few. We place high value on in-house training and eduction of our future skilled workers, as we have made the experience that those former trainees will develop to highly skilled people with a special relation to the company, its products and customers. A lot of our employees are working with us for more than 10, 20 or even 30 years.

As an internationally-active company, we set high value in multicultural understanding and cooperation, as every culture and nationality brings its very individual styles and advantages. Thus we can count with people from different countries all around the world working in Krah, like Turkey, Poland, Russia, India, Iran, Czechs, Italians, Libanese and Kazakhstan, just to name a view, being able to communicate in 15 different languages.

Beside our periodical newsletter, we have also published a book “the handbook on lager plastic pipe”, of which the second version will be published soon.

With an eye to the future, we attach great importance to making the world a little better for our children and grandchildren, by producing a long-lasting, environmental-friendly and sustainable pipe system. Hopefully one day all people on this planet will have unlimited access to the most precious good we have: water. Both fresh drinking water, as well as a reliable sewage system are crucial for a good and healthy life and we hope that we can do at least a very little part to make this happening.

As much as the fresh and sewage pipe systems have developed and improved during the last years, we also find it very remarkable, how communication systems have changed during the last 50 years. First, there was the telegram and the normal letter, than, there was the great – and incredibly expensive invention of the telex, which already brought the world a little closer and give us the possibility to communicate with our customers abroad “live”, even with only few words and at high costs, it made it a lot easier to exchange information quickly. The fax machine was then the next big step before the internet with its emails and then the mobile phones changed everything! Nowadays everything is focused on social media, we are communicating with our customers and partners via email, phone, messenger services, internet platforms like linkedin, youtube, twitter and Instagram. There are so many ways to exchange information now, and everything is moving so fast, that sometimes you have to control yourself in not losing the real life by only concentrating on the virtual life.

We hope that this basic idea will last for a long time and we are very much looking forward to improving the world a little together with you!