Sewage

Sewer systems made of profiled Krah pipes have been used for more than 35 years in all areas of local and industrial drainage.

The Krah group offers a modern sewer pipe program with manholes, fittings, and safe pipe joint systems for the planning of sewer treatment plants.

Gravity Pipes made out of PE80 / PE100 and polypropylene can have inner diameters ranging from DN/ID 300 mm to DN/ID 5000 mm. The standard length of 6m enables easy transport, quick handling and less jointing.

Storm Drain

Krah is a competent partner for system components for drainage and degassing of landfill sites.

Many landfill sites have been successfully equipped with profiled drain pipes and manholes.

Krahs developments have set new standards for soil and ground water protection. Drain shafts with control systems are available in diameters of up to DN/ID 5000 mm.

Pressure Pipes

Pressure pipe diameters may range from DN/ID 300 up to DN/ ID 5000 mm made either of homogenous polyethylene, polypropylene or a compound of polyethylene reinforced with fibers to unite the well-known properties of thermoplastics with the significant characteristics of fibers.

Fields of application spread from potable to industrial uses or also special applications. Pressure may range up to 10 or 16 bar.

Marine Application

Water outlets are used for the discharge of liquid and gaseous substances at the base of rivers and the sea.

For the construction and operation of such pipelines Krah pipes offer considerable advantages, such as the elasticity of the pipeline and therefore optimum adaptation to the area, low weight, secure and strong jointing technology and seawater resistance.

The pipe stiffness is exactly adapted to the respective requirements because the appropriate profiles are selected for every individual project.

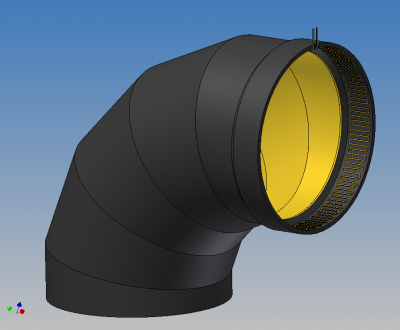

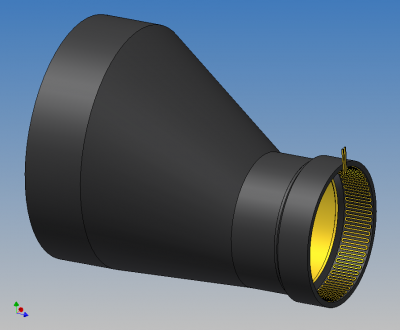

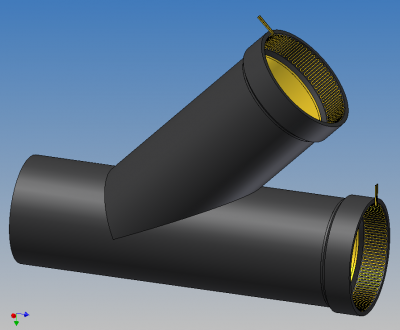

Fittings

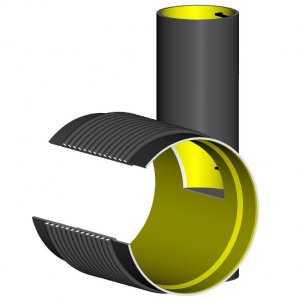

House connection branch

PE pipe systems fulfill the highest requirements regarding tightness, long lifetime and installation.

These high demands are being strictly and consequently met by HAS-fitting. Suitable for a new installation as well as a later integration in an open construction, the house connection pipes and lateral pipes in diameters DN 150(OD 160 SDR 17,6) and DN 200 (OD 225 SDR17,6) can easily, quickly and economically be jointed to the main pipe out of PE.

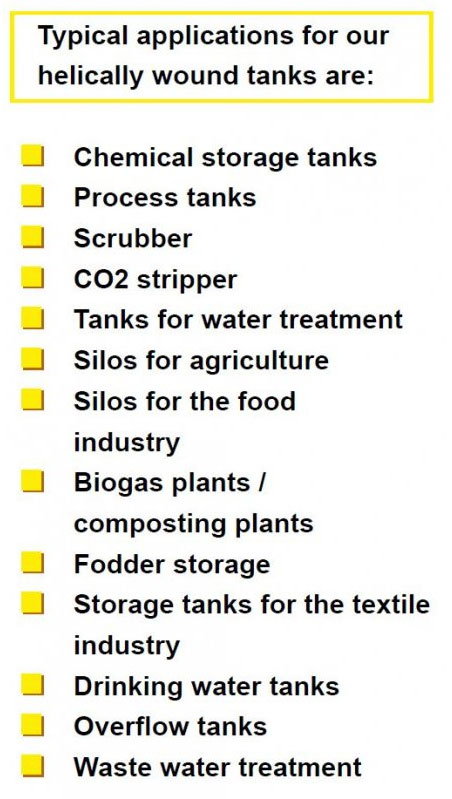

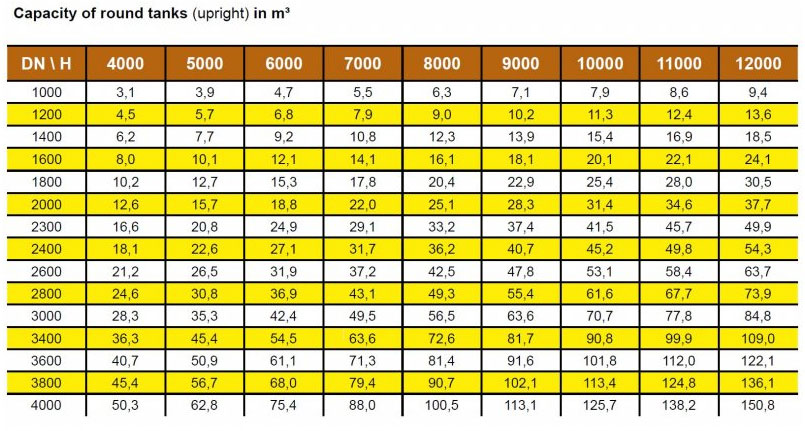

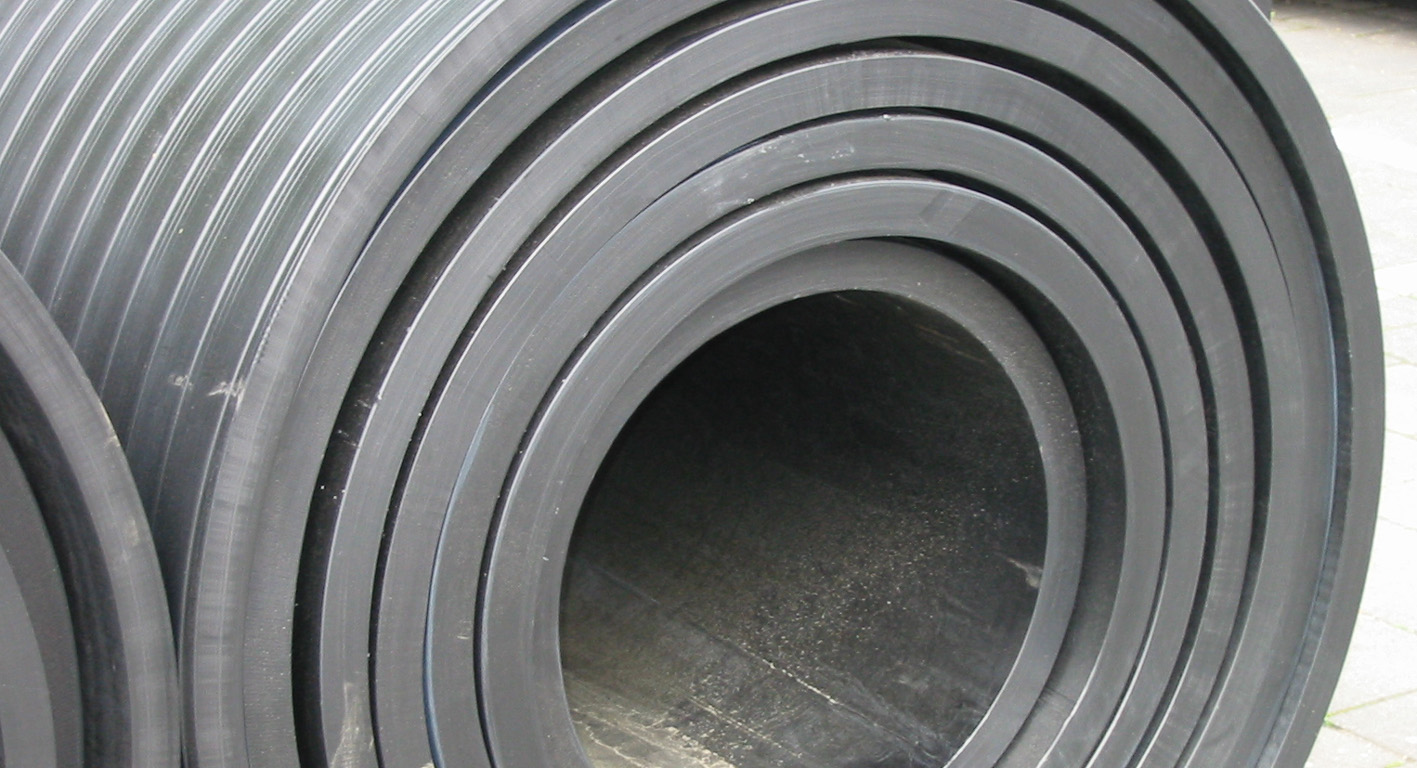

Tanks and Apparatus

Tanks can be filled with various volumes (liquid, solid, organic, inorganic). A major advantage of these storage tanks is their varying wall thickness : the bottom is made from thick wall material while the top is rather thin.

This enables an economic manufacturing, stability and an uncomplicated handling.Basically the tanks are large-volume custom-designed tanks with a capacity of 1m³ to 150m³. The tanks are completely tailor made and can be extended easily even after they have been finished.