11 Mai 2018

Verfasst von Lisa Bläcker. Veröffentlicht in Krah - News

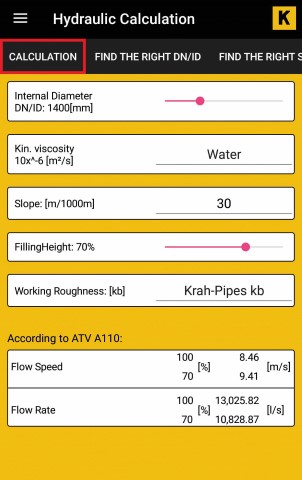

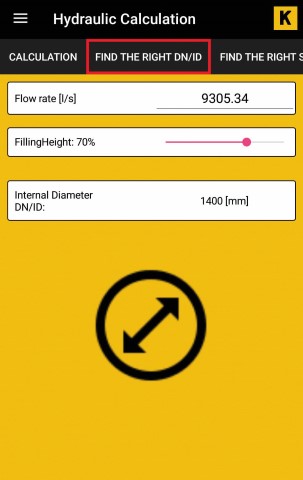

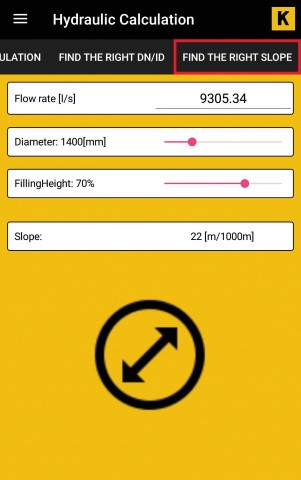

Krah pipes are often used for pressure applications, whether the requested pipe material is a standard High Density Polyethylene (HDPE) or Polyethylene reinforced with glass fibres (PE-GF). For the flow-characteristic and pressure loss the surface quality is essential, since the surface-roughness affects the friction between fluid and pipe wall. Polyethylene pipes (HDPE and PE-GF) provide in general very low roughness values in comparison to steel or concrete pipes. The low roughness and the kind of waxy surface can also avoid incrustations which is another point to reduce the pressure-loss.

Furthermore also the jointing procedure can be important. Any interruption of the surface generates additional turbulences, which increase the pressure loss. In the pipe design that aspect should be considered. A smooth surface after jointing is very preferable, e.g. by using Electrofusion socket / spigot joints.

Especially in comparison with other pipe materials like concrete or steel the advantages of Polyethylene pipes become clear after calculation. By using Polyethylene pipes very often the necessary pipe diameter can be reduced because of better flow-behaviour and less pressure loss!

1. Pressure loss

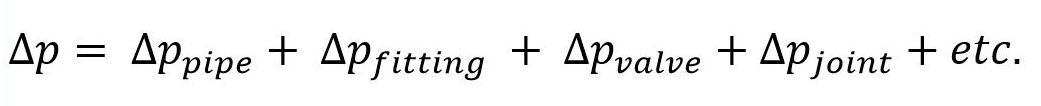

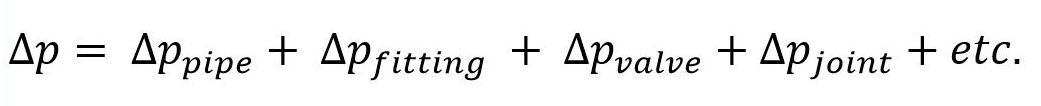

The pressure loss in pipe systems is the sum of all pressure losses for any element of the pipe system. All fittings, valves and constructions have an individual pressure loss and even the pipe joint can affect the pressure loss.

1.1 Pressure loss of straight pipelines

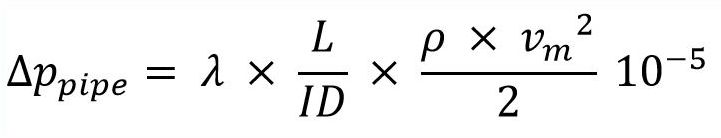

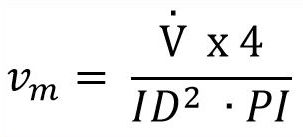

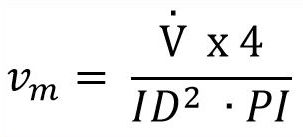

The pressure loss for pressure pipes can be calculated by using the following Darcy-Weisbach-equation, first time established by Jean François d’Aubuisson de Voisin in the year of 1834.

Weiterlesen