Upscaling of pipe stiffness results acc. to ISO9969 for large, structured wall polyethylene pipes

1. Introduction

Structured wall pipes manufactured according to DIN EN13476Ii should be classified into SN classes (Stiffness Nominal) in accordance with ISO13966ii . ISO9969iii sets the rules & conditions for the actual testing. The larger the pipe diameter to be tested, the more difficult it is to find suitable laboratory equipment. Many pipe producers and even independent third-party laboratories have a limitation on the largest testable pipe. This paper aims to prove that a semi-theoretical upscaling of the physical test-result regarding pipe stiffness can be used to prove that the stiffness of a larger diameter pipe can be tested on a smaller references diameter.

The SN-value has no relation to the actual needed stiffness according to site conditions.

2. Methodology

At the production plant, two pipes will be produced with the same machine setup and material, only the tool for the pipe diameter will be different. In a first step, a theoretical SN-class is calculated based on the geometrical data of the wall structure. From each pipe, three test samples will be cut and prepared for lab-testing. Both pipes will be tested according to ISO9969. Prove that the equation will reach the same results as the physical testing.

3. Semi-theoretical approach

Basically, all physical tests will prove the bending stiffness - flexural rigidity (M) of the profile/structured wall depending on the used raw-material properties.

![]()

Based on the standard equation for calculating a SN-value:

Where Es is the short time e-modulus of the material [N/mm²], Ix the specific area moment of inertia [mm^4/mm], Dm the mean pipe diameter [mm], SN the nominal pipe stiffness [kN/m²] and e the distance of inertia of the structured wall [mm]. A new formular will be generated to scale up the stiffness test results from a reference diameter (Dref) to another demanded diameter (DD) by using the same “bending stiffness” (M) of the structured wall and the result of a practical stiffness test (SNRef) for a pipe with the reference diameter (DRef).

Equation 3 is the basis to upscaling the SN value from one diameter to another.

4. Practical proof

Two different pipe diameters were produced (production date: 3rd of August 2024) with the same machine (KR900) and the same material specification and the same wall structure. One pipe with an DN/ID1500 and another with DN/ID2000. The products were produced in Estonia at Krah Pipes OÜ. Krah Pipes OÜ has a stiffness testing machineiv to perform constant speed stiffness tests according to ISO9969, with a maximum testing range of DN/OD65 – DN/OD2340. The stiffness test was made on the 8th of August 2024. The same wall structure (Type: OP) was produced on a pipe with an internal diameter of DN/ID1500 and DN/ID2000.

a) Profile shape

The produced structure wall pipe is made of PE100 materialv. Short term E-modulus is 1080 [N/mm²]vi, the profile dimensions are theoretical and real:

The used core-tube in both pipes is from the same batch. The real pipe geometry varies slightly from pipe to pipe resulting from the specifics of the production process. The dimensions achieved on both test pipes are comparable with each other, thus fit for the purpose of this proof. The mean distance of inertia is (e) = 56,4 [mm]. The distance of inertia was determined using a software ProJen based on a graphical analysisviii.

Sketch 1: Sketch of the used wall structure

We consider a lower stiffness because the height of the structured wall is lower than in the theoretical approach.

- The pipe DN/ID 1500 is 0,7% heavier than the theoretical approach.

- The pipe DN/ID 2000 is 2,1% heavier than the theoretical approach.

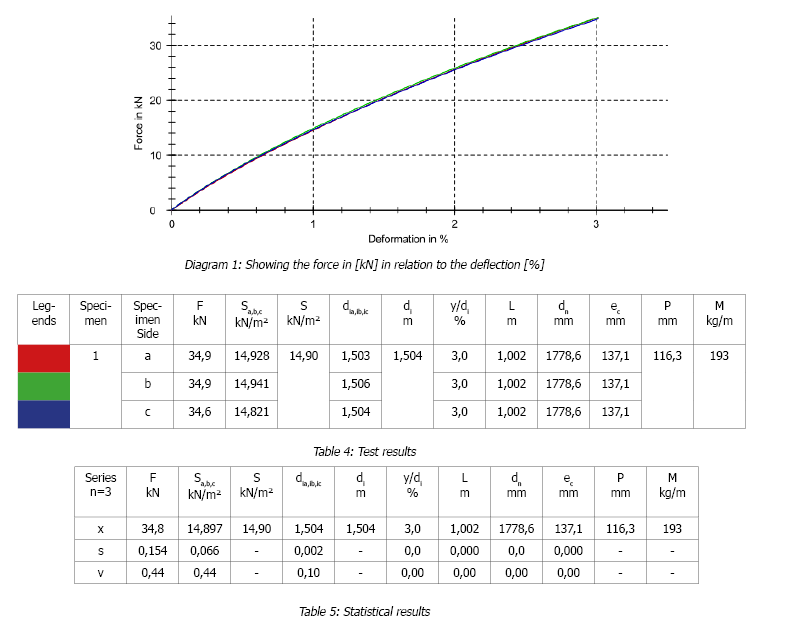

b) Test results for DN/ID1500

The produced pipe DN/ID 1500 with the profile type OP75-067.83 was cut in three different test specimens. The preload was set to 375 N and the test speed was 45 mm/min.

The test result for the pipe size (DRef) DN/ID 1500 was SNRef = 14,90 kN/m².

c) Test results for DN/ID2000

The DN/ID 2000 pipe produced with profile type OP75-067.83 was cut in three different test specimens. The preload was set to 500 N and the test speed was 60 mm/min.

The test result for the pipe size (DD) DN/ID 2000 was SNRef = 7,01 kN/m².

d) Semi-theoretical approach

Upscaling the test result according to equation 3 with the following values.

DRef = 1500 [mm] + 2 * 56,4 [mm] = 1.612,73 [mm]

SNRef = 14,90 kN/m²

DD = 2000 [mm] + 2 * 56,4 [mm] = 2.112,73 [mm]

![]()

The nominal stiffness for the required diameter (DN/ID2000) is 6,63 [kN/m²], based on the semi-theoretical approach (the real stiffness is 5,774 % higher).

e) Reverse-calculation

As a short (untypical) calculation, the results and values for the pipe DN/ID2000 are used to get the semi-theoretical results for DN/ID1500.

DRef = 2.112,73 [mm]

DD = 1.612,73 [mm]

SNRef = 7,01 [kN/m²]

SND = 15,75 [kN/m²]

(The real stiffness is 5,774 % lower)

f) Result:

The approach was that using the semi-theoretical equation to upscale the stiffness would lead to a conservative result:

- DN/ID 1500 = SN 14,90 kN/m² (tested)

- DN/ID 2000, SN = 7,01 kN/m² (tested)

- DN/ID 2000, SN = 6,65 kN/m² (upscaled, based on DN/ID1500 test result)

5. Limitation

More test specimen and different pipe structures should be tested.

It is important to check whether there is a maximum relationship between the diameters. The production technology is not able to produce in those low tolerances to avoid different results. It is impossible to guarantee exactly same parameters on two different pipes, thus generating some variability on proofs like this.

6. Conclusion

The theoretical approach of this work was confirmed by practical testing. The theoretical approach is more conservative and will give a certain margin of safety. The purpose of this work was to show that it is possible to reliably estimate the stiffness of larger diameter pipe, by using a semi-theoretical approach. This approach is combining real laboratory testing of smaller diameter pipe and upscaling the real test result to the intended larger diameter pipe with the same profile. It was proven that the proposed semi-theoretical approach is conservative and yields lower stiffness of the larger pipe, than the actual testing revealed the stiffness to be, thus providing a certain safety margin by using such approach.

There are several practical implicatios of the described procedures. First, producers and third party independent laboratories can use their existing equipment to certify larger range of pipe diameters, thus eliminating the need for large investments into bigger machines. Verification and certification procedures will be simpler and faster as there are more third party independent laboratories available. Another benefit is that specific profile requirements for large diameter pipes can be verified without timeloss using existing labortories at producer’s facilities, thus making quality verifications easier for the customers. Overall, this is a very sustainable approach, as larger pipes no longer need to be transported.

iDIN standard for plastics piping system for non-pressure underground drainage and sewerage – structured-wall piping systems

iiDIN standard for thermoplastics pipes and fittings - nominal ring stiffnesses

iiiDIN standard for thermoplastics pipes - determination of ring stiffness

ivType: Zwick-Roell BS1-FR100TEW.A2K.008 (serial number 190232/2009)

vBorealis BorSafe HE3490-LS in bags

viBorealis Certificate

viiMickey is a Software provided by the manufacturer.

viiiwas calculated by the Steiner Theorem